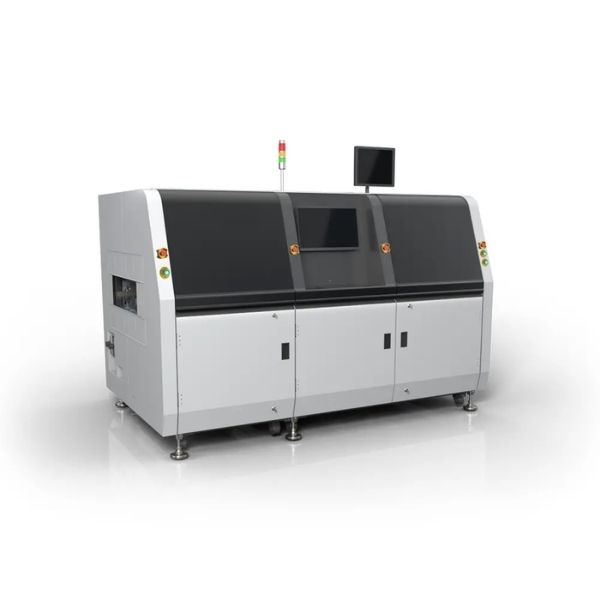

JNS Integrated Selective Soldering

● Spray Fluxer + Preheating + Soldering module, integrated design, flexible configuration and free expansion;

● The point soldering module and the group soldering module are freely matched and combined;

● The most efficient selective soldering module;

● Sectional modular transmission structure.

Description

| Model | JNS-450 |

| Parameters | |

| Dimension L×W×H | 2600×1800×1650mm(1-2 pot) |

| Transporting System | |

| PCB Width | 60-450mm |

| PCB Length | 120-500mm |

| PCB Top Space | Max :120mm |

| PCB Bottom Space | Max :50mm |

| PCB Edge Size | 4mm |

| Conveyor Height | 900±20 |

| Conveying Speed | 0.2-10m/min |

| PCB Weight | Max:5kg |

| Fluxer Module | |

| Flux Capacity | 2L |

| The Size of Flux Nozzle Tube | 130um |

| Flux Width | 2-8mm |

| Preheating Module | |

| Bottom movable Infrared Heater | Max:14kw |

| Temperature Range | Room Temperature-250℃ |

| Top Air Heater | Max:6kw |

| Soldering Module | |

| Min Diameter of Solder Nozzle | ¢2/4.5 |

| Wave Height | 3〜5mm |

| Solder Pot Capacity | 8KG(Solenoid Pump)/13KG(Mechanical Pump) |

| Soldering Temperature | Max:350℃ |

| Heating Time | 40min/(Mechanical Pump 300℃)/75min/(Solenoid Pump 300℃) |

| Pot Heating Power | 1KW/ Single pot |

| Location Speed | X/Y:2-200mm/s |

| Temp.Control Accuraey | ±2℃ |

| Soldering Accuracy | ±0.25mm |

| Control System | |

| PC Operating System | Windows 10 |

| Process Visualization | CCD Visual |

| Software Language | Chinese and English Changeable |

| Programming Mode | Inline/Off line Programming |

| Data Import | Gerber、ImageꢀIntroduction |

| Air System | |

| Air Supply | N2/O2 |

| Required Pressure | 0.4-0.8Mpa |

| N2 Consumption | Eachꢀconsumesꢀaboutꢀ1.5-2ꢀm³/h |

| N2 Concentration | ≥99.999% |

| Electrical Parameter | |

| Power Supply | AC 380VAC 3Φ5W 50/60Hz |

| Consumption | 35KW |

| Air Exhaust | |

| Air Duct Diameter | ¢200mm x3 |

| Exhaust Air Rate | 360 m³/h |

| The above contents are subject to change without further notice! | |