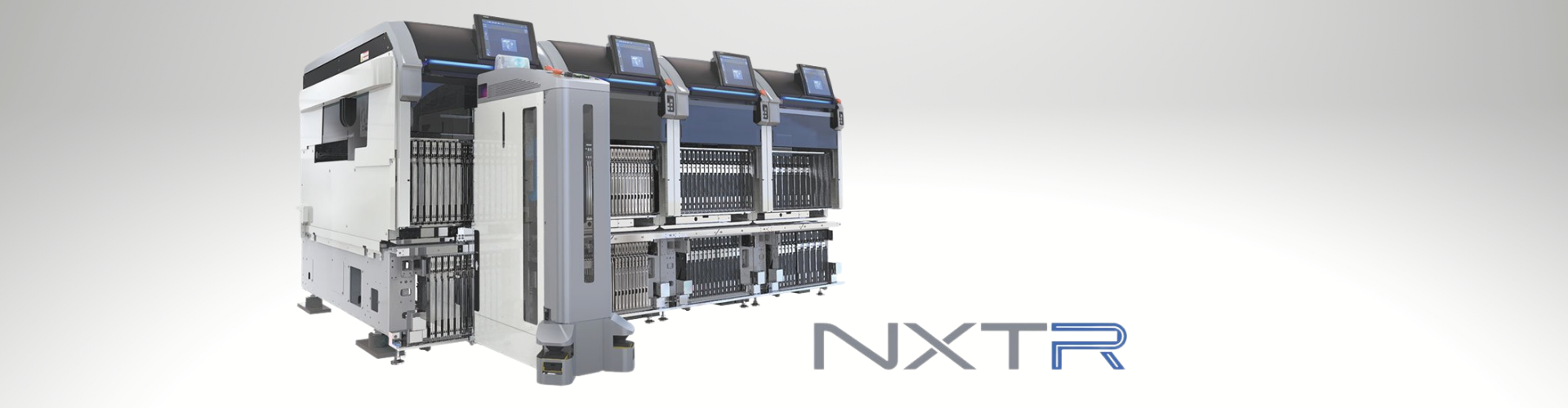

FUJI NXTR SMART FACTORY PLATFORM

The newly developed automatic feeder exchange system frees the operators from changeover and supply work and offers additional functions that ensure the maintenance of high quality and productivity.

- Automatic feeder change

Since the Smart Loader handles the changeover and parts supply according to the schedule, the workload on the line can be reduced and efficient production can be achieved.

- Load large quantities of parts

Through the use of new types of feeders and base buffers, the number of parts that can be loaded is considerably increased. A wide range of production can be supported by the smart loader.

- World-class productivity

Achieves a first-class placement speed with the unique Fuji-revolver head technology. This contributes to even higher productivity.

- Flexible support for changes in production

The three newly developed heads offer excellent part handling and flexibility without reducing the production rate, even if in the next production a different range of parts is used.

- Reliable placement with sensor technology

From part pick-up to placement, sensor technology is used to perform various checks. This allows a stable placement with high quality.